In line with rapid advancements in regenerative medicine and stem cell research, the potential of 3D printing biotechnology in regenerating organs and lost limbs has caught much attention. In that case, 3D printing of human organs with the use of stem cells would revolutionize the organ transplant procedure making up for the acute shortage of organ donors worldwide.

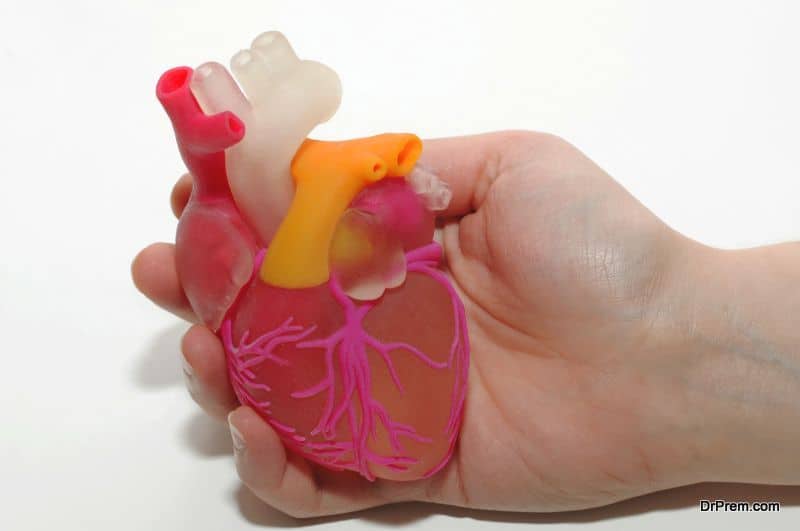

Scientists have already come out with the 3D printed prototype of the human heart. Imagine the suffering of 26 million heart failure patients worldwide. A customized artificial heart with 3D printed heart stem cells can provide an invaluable solution to this life-threatening condition. This advanced 3D printing mechanism can also bring a radical change in the prosthetic industry, enabling humans to regenerate lost limbs from their own stem cells.

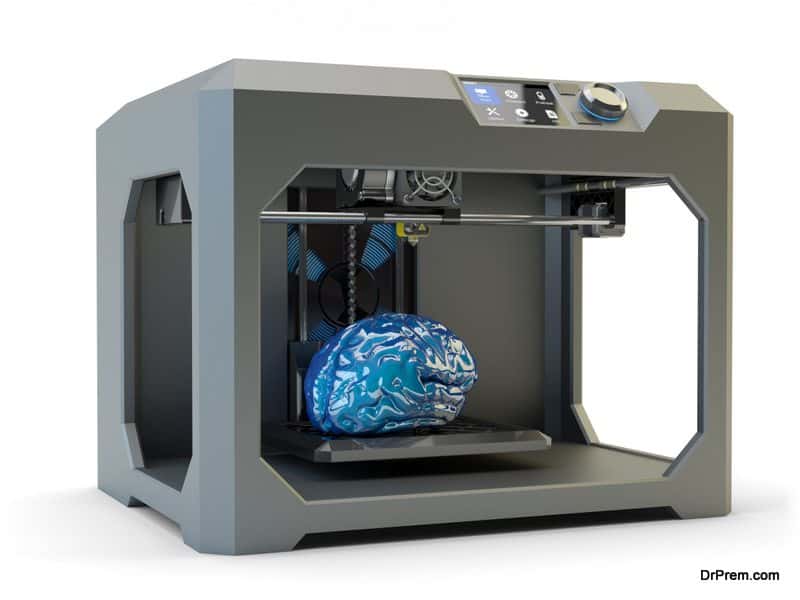

What is 3D printing of organs?

Researchers at the Wake Forest, North Carolina, have created a 3D printer technology that has the ability to print bones, tissues, and organs with the potential to be implanted in the human body. The details of this research are published in the Nature Biotechnology journal.

Almost similar to the typical 3D printers, a controlled computer nozzle of the advanced printer imprints on the layers of materials in a precise manner. These embedded layers eventually get hardened and produce the desired shape and structure of the organ.

While a typical 3D printer uses layers of molten metal and plastics, Wake Forest researchers came up with a specific material known as hydrogels. These are water-based solutions containing human cells. The multiple nozzles of the printers are fed with hydrogels and other biodegradable materials which are needed to impart the right structure and strength to the tissue to be printed.

Bioprinting- 3D printing of human organs with the use of stem cells:

This newly advanced medicine, ready to take off, has been generating enough excitement, expanding the horizon of 3D printing technology. In this process, stem cells are harvested from the human body and are allowed to grow in a petri dish. Induced Pluripotent stem cells (IPS) are mostly used to replace dead tissues, forming the base for 3D printing of human organs with the use of stem cells.

This becomes the mix like printing ink to be fed into the nozzles of the printer. The 3D printer is programmed where different types of cells are arranged with other materials to print the desired 3D shape of the organ.

Creating 3D models in files in a 3D printer is usually a time-consuming process. But Nano Dimension, an Israeli company, claims to have tested a printer capable of producing IPS cells much faster.

A 3D printed heart implant can function like a real one:

In another groundbreaking advancement in 3D printing biotechnology, scientists have been able to create an artificial heart from silicone, which beats just like a normal human heart. Deviating slightly from the 3D printing of human organs with the use of stem cells, this new invention has taken the cardiac medicine few steps ahead, where damaged hearts can be replaced without the need of a transplant.

The prosthetic science has been advancing in leaps and bounds with the advent of soft robotics helping in creating more flexible limbs and organs. The scientists have applied almost the similar techniques in developing a complex organ as the 3D printed heart implant.

This artificial heart is almost similar in size to that of the patient and replicates the function in more or less the same manner. This silicone heart has the essential chambers, the left, and right ventricles along with an additional chamber that helps in pumping.

The inflation and deflation of the heart with the pressurized air in the third chamber would force the blood through the ventricles. The same has been tested with a liquid as viscous as blood.

Slightly heavier in size than the normal heart, it can be a much better alternative than the mechanical pumps used in heart failure patients. The big hurdle to overcome for this 3D printed heart implant is that it can last only for 3000 beats or roughly half an hour.

The scope of 3D printing of limbs:

Though this may be one of the successful applications of 3D printing of human organs with the use of stem cells, at this moment, the technology hasn’t advanced that much to print limbs.

Few companies may be claiming to have successfully created 3D printed prosthetic limbs, but the practical application needs to be checked. Considering the immense potential of 3D bioprinting, printing a real limb seems to be quite logical; something which might soon see the light of day.