Thus far, only human arms have been used in the manufacturing industries. Now, with the advancement in technology, new arms known as industrial robotic arms are finding their myriad applications in a plethora of industries. They work in the same way as human arms; however, they are more accurate and faster.

Among all the other robots in the manufacturing industries, industrial robotic arms are the most common as their application are very relevant in the production line. The robotic arm has a wrist, forearm, elbow and a shoulder; and, hence, resembles a human arm.

Types of industrial robotic arm

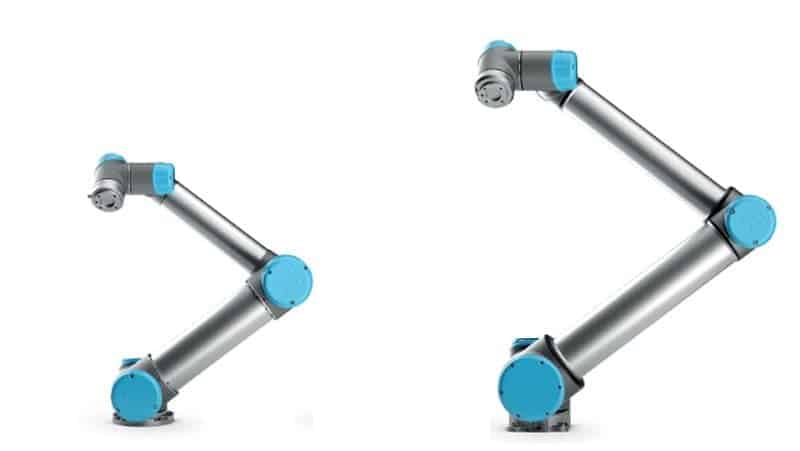

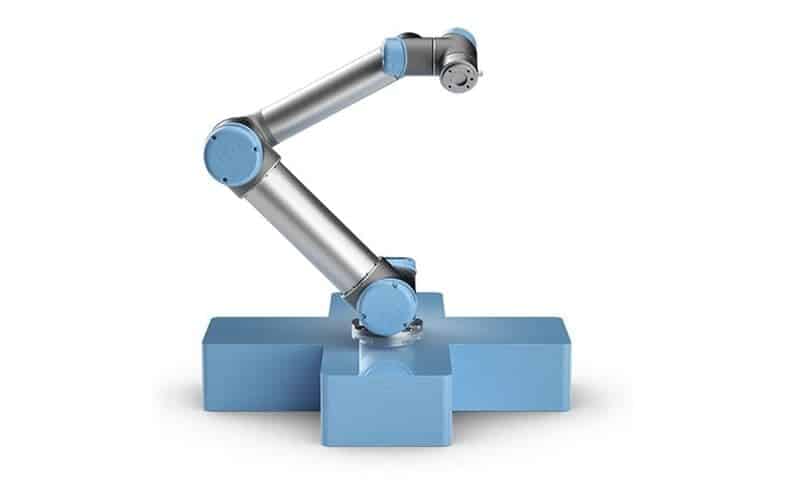

Collaborative robot arm

Collaborative robot arms are manufactured and designed in a way that they are able to follow some safety standards to avoid hurting the human in its workspace. They can therefore work in close contact with humans.

Collaborative robot arms are manufactured and designed in a way that they are able to follow some safety standards to avoid hurting the human in its workspace. They can therefore work in close contact with humans.

Cartesian Robot arm

Cartesian robot arms have three linear joints that use the standard X-Y-Z Cartesian axes. They are able to do three translations using linear slides.

Cylindrical robot arm

At the base, this robot has at least one rotary joint and one prismatic joint that connect the links. The rotary joint moves in a rotational motion at the joint axis whereas the prismatic joint uses a linear motion. This industrial robot arm has a cylindrical-shaped work envelope where it operates in.

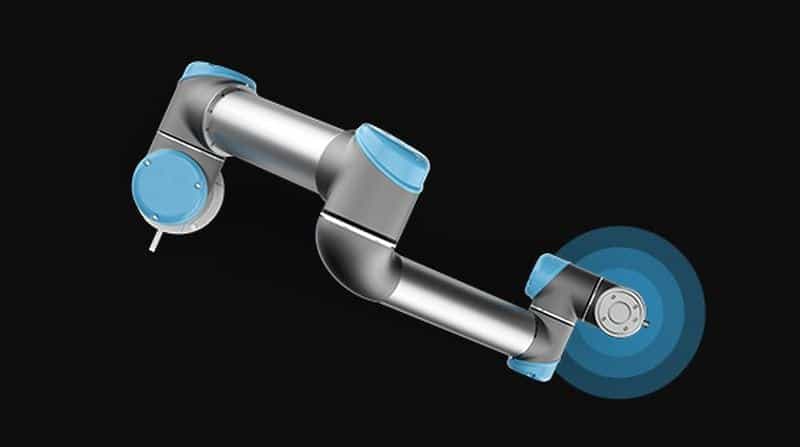

Articulated robot arm

In this type of industrial robotic arm, the arm is connected to the base and is paired with a twisted joint. They are most commonly used for their flexibility; hence, they have additional range of motion which is possible in each joint. They are mostly used for complex applications such as welding, soldering and drilling applications.

SCARA robot arm

This robot arm features two parallel joints to allow full movement in the selected plane. Its design is primarily cylindrical. It is typically used for pick and place work.

Polar robot arm

They are also known as spherical robots. The arm is attached to the base with a twisting joint, one linear joint and two rotary joints. A polar coordinate system is formed by the axes for creating a spherical work envelope.

Applications of industrial robotic arms

Below are major applications that industrial robotic arms are put to.

Arc Welding

One of the driving forces of utilizing an industrial robotic arm for arc welding is to improve the safety of the employees. That is from the risk of inhaling the hazardous fumes and from arc burn. Moreover, using a robot arm will make the whole process faster.

Materials handling

These robots are used to move, pack and select items. Additionally, they can move parts from one piece of equipment to another. This reduces the direct labor cost from the hazardous and tedious work done by human labor.

Picking, packing and palletizing

Prior to distribution or shipping, products are handled several times. When the process is done by utilizing an industrial robotic arm, there is an assurance of increased speed and accuracy; thus, lowering the production cost.

Painting

Painting requires consistency to produce a high quality end product. A robotic arm is an effective tool to ensure this is achieved. Additionally, it eliminates exposing workers to the fumes produced by the paints.

Assembling

Most assembling procedures are tiresome and tedious. Hence, utilizing a robotic arm to perform this task is important. It will not only improve the quality of the product, but will also reduce operational costs.

Machine Tending

The automated process helps load and unload raw materials to the designated machinery for processing. The operator oversees the machine as it does its job.

Gluing, adhesive sealing and spraying materials

The industrial robotic arms used for this purpose have numerous arm configurations that allow the robot to reach difficult areas in the operation.

With the various types and applications of industrial robotic arms, it is evident that these robots are really the future of manufacturing industries. Moreover, the new generation robots are now collaborative; hence, the workers and the robots can work closely to produce the desired outcomes.

Article Submitted By Community Writer